Non-metal laser cutting machine

Improving Business Growth with New Technology

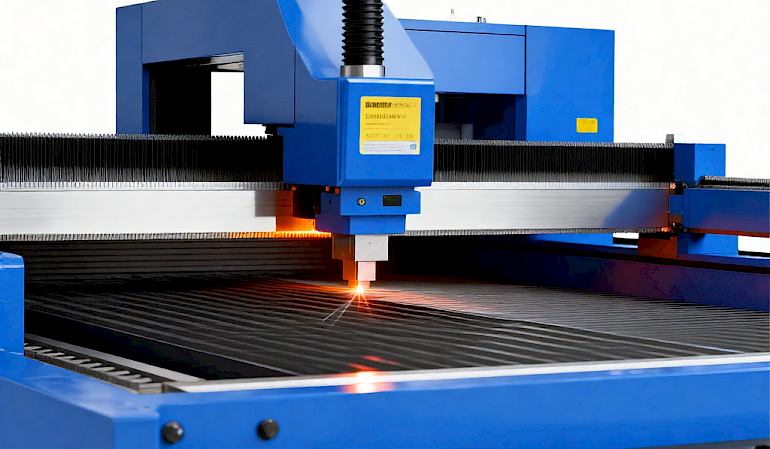

Laser Cutting Machine: Brief Product Introduction

A laser cutting machine is a high-precision mechanical device integrating optics, mechanics, and electronics. It utilizes a focused high-power laser beam to melt or vaporize materials, achieving clean, precise cuts with minimal heat-affected zones. Key components include a laser generator, beam delivery system, CNC motion control, cutting head, and cooling unit.

Core Advantages:

●

High Precision: Smooth, burr-free edges and tight tolerances.

●

Efficiency: Fast cutting speeds and automated nesting for material savings.

●

Versatility: Cuts metals (steel, aluminum) and non-metals (acrylic, leather) across industries like automotive, aerospace, and electronics.

●

Flexibility: Handles complex 2D/3D patterns via CNC programming, no mold required.

Key Types:

●

Fiber Laser Cutters: Ideal for metal sheets (max thickness ~20mm).

●

CO₂ Laser Cutters: Suited for non-metals (wood, plastics).

●

YAG Laser Cutters: Used for precision cutting of thin metals.

Widely applied in manufacturing, advertising, and crafts, it combines cutting-edge laser technology with CNC precision for superior performance.

Keywords: Laser Cutting, CNC, High Precision, Metal/Non-Metal Cutting, Industrial Machinery.

Leave a Comment